Reaching the launch pad is a monumental milestone for any rocket company, but building the launch pad is an entirely different challenge. It is essential for launching a rocket, yet it often remains an unsung hero in the background. At Rocket Factory Augsburg (RFA), we’re dedicated to sharing the story of our “Stage Zero” and giving you a behind-the-scenes look at our process.

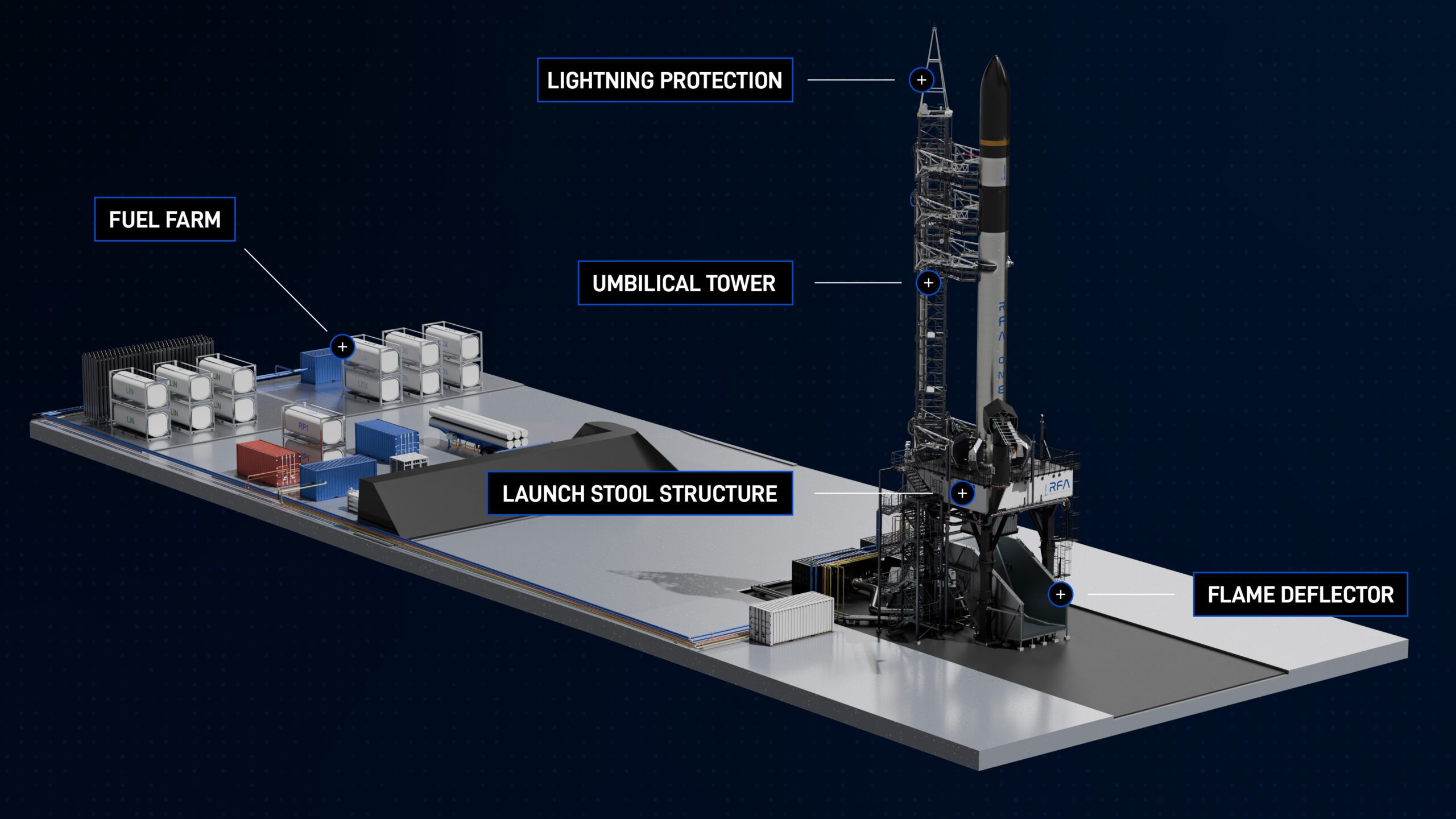

While most people focus on the rocket itself (which is completely fair), we delve deeper into the question: “But how do we make it actually happen?” The entire process is incredibly complex and requires meticulous planning. Our launch pad must store, amongst others, thousands of liters of fuel, LOx, Nitrogen, and Helium. It then has to fill our three rocket stages at precise temperatures, to a specific time, provide power to all systems and sensors, and protect itself from the immense power of our nine Helix engines roaring to life.

Believe it or not, we didn’t just close our eyes and point to a map.

Choosing SaxaVord Spaceport as the base for our flight operations was a decision made after careful consideration of various factors: Firstly, SaxaVord and RFA are both private companies who share the same approach of cost-efficiency, a fast pace and “go-get-it”-mentality. Secondly, Shetland has a rich oil and fishing industry with existing infrastructure (e.g. industrial harbors, tool stores, suppliers). Finally, it is perfectly located for launches into polar low earth orbits.

While launching from the equator provides additional speed from the Earth’s rotation, this advantage is primarily relevant for higher or further orbits (e.g., GEO, Lunar, or interplanetary). For our purposes, proximity to the equator is not a crucial factor since we will be launching in a direct north/south direction. We’re primarily targeting polar and sun-synchronous orbits as that is the optimal location for the more commercially interesting constellations and Earth Observation (EO) satellites.

Now, as we set the scene in Scotland, building a rocket launch pad involves much more than just concrete and steel.

Our team of engineers has worked tirelessly to design and implement the technical infrastructure needed to support our rockets. From fueling systems to communication with, and erection of the RFA ONE, every detail has been carefully planned to make sure we have a safe, efficient, and successful launch. Let´s have a look at some of the main elements:

The process of building Stage Zero was a journey marked by challenges and collaboration. In true RFA fashion, the design philosophy for the launch site was to aim for low-cost and standardization. We achieved this by building the site from the ground up and designing all our systems and modules to fit into standard shipping containers. It made it easy to transport everything from Augsburg to Shetland and beyond. Our launch site can be packed down and put up anywhere in the world, further adding to our flexible and low-cost approach.

Ultimately, designing and building Stage Zero has been a challenging but highly rewarding experience for everyone involved. Our recent first stage hot fire has shown that the systems are working well and that we can now push on with finalizing everything for our first test flight. Our hope with this blog post is to shine a little more attention on this marvel of engineering.

The rocket is one thing – what it takes to really get this thing off the ground is a story all of its own.

Interested in launching with us? Enter your details and specifications to explore tailored solutions.

If you’re interested in receiving access to our Payload Users Guide for our Redshift OTV, please enter your details below.

If you’re interested in receiving our press kit, please enter your details below. We’ll review your request and get back to you ASAP.

If you’re interested in receiving access to our Payload Users Guide for our RFA ONE, please enter your details below.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Undefined cookies are those that are being analyzed and have not been classified into a category as yet.